Material & Finish Options

R.J. Thomas Mfg. Co. provides a wide variety of materials and finish choices on the many different products that we make.

Jump to: Powder Coated Finish | Aluminum | Lumber | Thermoplastic Coated Components | Expanded Steel | Perforated Steel | 100% Recycled Plastic

Hot Dip Galvanized Finish

Selected Pilot Rock bench and table frame components, lantern holders, trash receptacle holder components, bike racks and two grills are available with a hot dip galvanized finish. This finish is applied after fabrication and welding to ASTM A123 specifications to maintain an average zinc coating of 2.0 oz. per sq. ft. of surface area. Use /G in model number for hot dip galvanized finish.

Hot dip galvanized finish products are ideally suited for humid coastal and island area environments. The combination of moisture and salt exposure causes any steel exposed by a scratch in the paint to quickly rust. Hot dip galvanized finishes involve a seven step liquid immersion process. These steps and the high temperature create a metallurgical bond where the iron in the steel products bonds with the zinc to achieve complete adhesion of the carbon (steel) product with the zinc (galvanizing) material. This process allows for complete coverage on all sides of the steel products – including the inside and outside of tubular products, such as picnic table legs.

Heat Resistant Black Enamel Paint

Pilot Rock grills and campfire rings are finished with a high heat resistant, non-toxic, matte (low gloss) black enamel paint. This silicone-based paint is lead and chrome free and formulated especially for Pilot Rock. It is capable of enduring temperatures exceeding 750 degrees.

Once cured, this creates a strong heat and scratch resistant coating, but is not fully cured upon delivery and will not fully cure until after its initial fire. The heat resistance in this paint is created by a silicone additive which needs a high temperature to cure leaving the paint somewhat soft and less resistant to scratching until its initial fire. Paint drips and small scratches that occur during shipping are often eliminated as the paint gels during its first fire. Larger scratches or scrapes can be treated with a high heat aerosol touch up paint and will blend in after the next fire. Annual maintenance is recommended to clean and spray any areas where the coating may be damaged. It is also highly recommended to remove the ashes from your fire pit regularly to allow any trapped moisture to evaporate.

Powder Coat Finish

Selected Pilot Rock bench and table components (steel and aluminum), lantern holders, trash receptacle holders and bike racks are available with baked on lead-free TGIC polyester powder coat finish that is applied in a multi-step process of material preparation and finish application. This process includes: detailed chemical cleaning; application of a corrosion inhibiting phosphate free, high pressure, high temperature bath; rinse; seal rinse; high temperature dry time; electrostatic application of the powder coat paint; chemical bonding to metal substrate in 430 degree industrial oven. The tough 3 mil thick coating offers a superior finish to liquid paints.

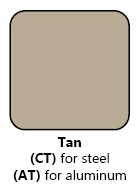

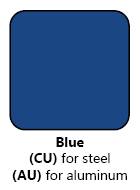

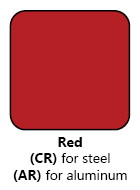

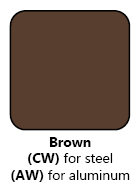

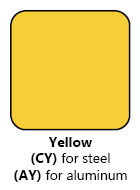

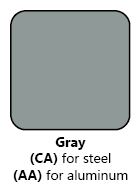

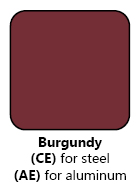

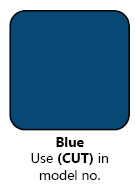

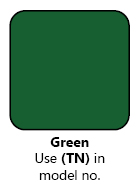

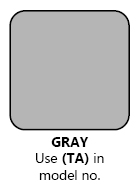

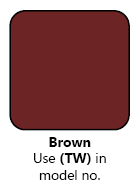

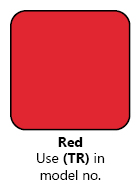

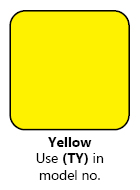

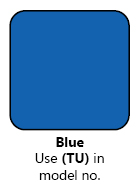

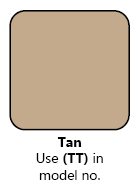

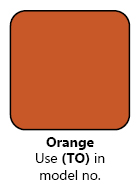

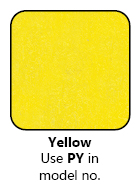

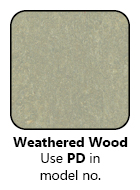

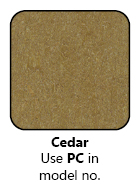

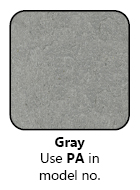

Model No. Example for products with Powder Coat finish: B40/**-4IB34. Replace (**) with letters indicating color choice listed below.

Textured Powder Coat Finish

We use a semi-gloss textured powder coat paint finish on our BPRT bear resistant trash/recycling receptacles, our BPFL bear resistant food storage lockers, and on the solid steel plate top/seats for the FCT-4 food court table. The application process is the same as described above.

Model No. Example for products with Textured Powder Coat finish: BPFL/***-15. Replace (***) with letters indicating color choice listed below.

Aluminum

Aluminum

Several select picnic tables and benches can be equipped with seats/tops or seats/back of aluminum planks. These planks are extruded 6063-T6 aluminum, equivalent in size to 2" x 10" (nominal) lumber planks. Four structural ribs provide rigid support and strength. The aluminum is clear anodized to specification 204 R1 for a clean, maintenance free finish. All plank ends are covered by an extruded, clear anodized aluminum end cap fastened into place. Table tops are made into single units (at the factory) by connecting the planks with one-piece end caps fastened across each end of the top. Aluminum planks are provided with precision fitted aluminum brackets and galvanized carriage bolts to attach planks to table or bench frames. Use AL in model number for aluminum.

Optional: Aluminum components (max. 12 ft. length) are also available with powder coated mill finish aluminum planks. See Powder Coat Finish description for details.

Untreated #1 Southern Yellow Pine

Untreated #1 Southern Yellow Pine

Untreated #1 grade Southern Yellow Pine, kiln dried to reduce moisture content. The lumber is ready for you to water seal, paint or stain. All lumber is precision drilled to facilitate assembly. All exposed edges are removed to 3/8" radius. Use UP in model number for untreated pine. Tables use 2” x 10” planks. All dimensions are nominal.

Treated #1 Southern Yellow Pine

Treated #1 Southern Yellow Pine

Treated #1 grade Southern Yellow Pine is pressure treated and kiln dried after treatment (KDAT) to reduce moisture content. Wood preservative (no arsenic) gives superior protection against termites, insects and decay. The lumber is clean to handle, dry and ready for you to water seal, paint or stain. All lumber is precision drilled to facilitate assembly. All exposed edges are removed to 3/8" radius. Use TP in model number for treated pine. Tables use 2” x 10” planks. Benches can use 2” x 4” or 2” x 10” planks (varies by model). Trash receptacles use 2” x 4” slats. All dimensions are nominal.

Construct ion Heart Redwood

ion Heart Redwood

Construction heart redwood is a popular alternative on benches. Select 3x4" (nom.). timbers are made from the interior grain of American Redwood. Redwood naturally resists decay. It is available only in the 3x4" (nom.) dimension. All lumber is precision drilled to facilitate assembly. All exposed edges are removed to a 3/8" radius. NOTE: other species of lumber such as cedar, fir and clear redwood may be available when in stock. Please inquire. Use CO in model number for construction heart redwood.

Indonesian Balau Hardwood Lumber

Indonesian Balau Wood is no longer available. Our supply has been depleted and it is cost prohibitive to replace.

Indonesian Balau Wood is no longer available. Our supply has been depleted and it is cost prohibitive to replace.

Balau is a very dense, tightly grained wood that is high in oils and resins making it very durable and resistant to the elements, insects, warping and twisting. It is a hard and heavy wood with dimensional stability. Balau’s high density makes it a popular choice for outdoor furniture, park benches, decks, cabinets, doors and more. R.J. Thomas Mfg. Co. is using #1 Grade clear Balau wood.

Balau has a fine, even texture that is smooth to the touch. Balau hardwood has similar characteristics to Teak, but is much stronger and less expensive than Teak. Balau is kiln dried to reduce the moisture content and to reduce any potential for warping, checking or cracking. Balau wood has an above ground life expectancy of at least 15 years (when untreated, no coating applied). When maintained on a regular 2-3 year basis the life expectancy will increase to 40 years or more. Balau wood can be stained, painted or sealed.

Balau wood (also known as “Bangkirai”) is grown and sourced from established and sustainable forest agencies. Using Indonesia’s SVLK wood legality, verification and chain of custody system, Balau wood is traceable to legal and sustainable sources. Balau does not come from tropical rain forests. It is a deciduous tree that grows in the dry, hilly terrains in the forests of Southeast Asia.

Other species of hardwood may occasionally be available. Please contact us if you require a special species of lumber.

Thermo Plastic Coated

Expanded steel, perforated steel, and formed steel products

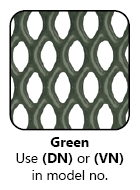

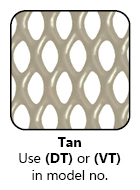

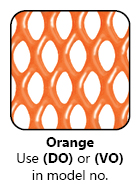

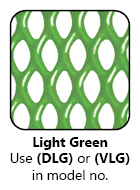

Selected Pilot Rock bench, table and trash receptacle products and components (expanded steel, perforated steel, cut/formed steel) are finished with a thermo-plastic coating in your choice of available colors. The thermo-plastic coating is PVC free and phthalate free.

The UV-stabilized thermo-plastic coating is applied in a multi-step process of material preparation and finish application, designed and formulated to create superior adhesion. After cleaning, the steel component is heated to 550-600 degrees (depending on the component). It is then lowered into an air-fluidized bed of colored polyethylene powder. This fluid powder fuses and bonds to the heated metal. The component is then baked at high temperature to cure the application.

This complete process of cleaning-heating-fusing-baking tightly bonds the powder to the metal, creating a durable, colorfast finish. The thermo-plastic finish includes a superior level of UV protection, does not support mold or mildew growth, and is impact resistant. We use a textured matte finish polyethylene. The matte finishes are less susceptible to marring and scratching (which is often a problem with gloss finishes).

Expanded steel, perforated steel, and formed steel components are assembled and reinforced with formed steel edge bands, angle irons and bars as appropriate to each product design. All components are single piece welded construction.

Our thermoplastic coating product has been tested by an independent lab, and given the highest rating of DNI - Does Not Ignite (and does not support combustion during or after flame exposure).

EXPANDED STEEL

Two types of component designs

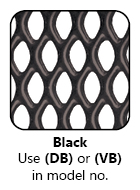

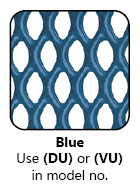

All of the D-Type and V-Type expanded steel that we use is 3/4-#9 material with a short longitudinal stretch. A shorter stretch means smaller “diamond” openings, which leaves more material (steel) per foot. The more diamonds there are per lineal foot is your indication that there is more steel left in the structure. Therefore, the components will be stronger. It is also called the “long way design, non flattened expanded metal”. “Non-flattened” means the steel is “on edge” around the diamonds. This provides a stronger, more rigid material.

D-Type

This standard duty table top/seat and other component design is built for your most common public applications and everyday use.

V-Type: Snow Load Rated

This design incorporates wider edge banding and more structural supports to create a table built for applications and locations that can be more abusive to the structure. This material is especially suited for high elevation areas where winter snow load can destroy average tables. The V-Type Snow Load design is available on WXT, WXTH, WPTS, XT, XTH, APT and APTX Series rectangular tables. This structure design is also used on some benches and square tables (but these products have not yet been snow load tested).

Example: Model XT/G-8DB table is equipped with standard duty top/seat structures for regular applications and everyday use.

Example: Model XT/G-8VB is equipped with the snow load rated top/seat structures for more extreme applications. You might also consider V-Type tables for installations where the tables could be subject to extraordinary public use and exposure.

Note: some V-Type components are used on certain benches and square picnic tables. These applications have not been tested or rated for extreme loads.

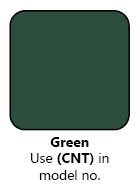

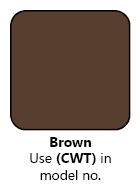

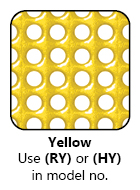

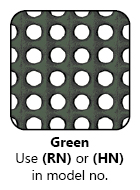

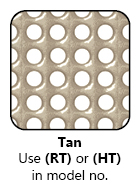

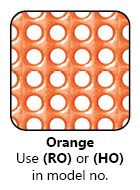

To request a color sample send Customer Service an e-mail.

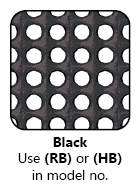

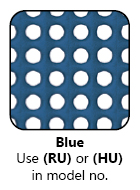

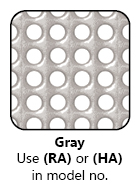

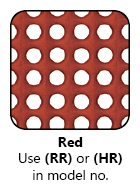

PERFORATED STEEL

Two types of component designs

All of the R-Type and H-Type perforated steel is 14 ga. with 9/16” diameter holes punched on 13/16” straight line centers.

R-Type

This standard duty table top/seat and other component design is built for your most common public applications and everyday use.

H-Type: Snow Load Rated

This design incorporates wider edge banding and more structural supports to create a table built for applications and locations that can be more abusive to the structure. This material is especially suited for high elevation areas where winter snow load can destroy average tables. The H-Type Snow Load design is available on WXT, WXTH, WPTS, XT, XTH, APT and APTX Series rectangular tables. This structure design is also used on some benches and square tables (but these products have not yet been snow load tested).

Example: Model XT/G-8RB table is equipped with standard duty top/seat structures for regular applications and everyday use.

Example: Model XT/G-8HB is equipped with the snow load rated top/seat structures for more extreme applications. You might also consider H-Type tables for installations where the tables could be subject to extraordinary public use and exposure.

Note: some H-Type components are used on certain benches and square picnic tables. These applications have not been tested or rated for extreme loads.

To request a color sample send Customer Service an e-mail.

Note: Colors and textures may vary. Colors shown are as close to the actual colors as possible. There may be variations in color translations over the Internet and by different monitors and printers used to view the colors. When selecting colors, keep in mind that Thermo-Plastic Coating for tables and seats and Powder Coating for frames may not be exactly the same color. That is, a Blue Thermo-Plastic Coating for seats and/or tops and a Blue Powder Coating for frames may differ slightly.

Steel Channel

Looks like 2x4 but has the strength of steel. Formed steel channel (SC) components approximate 2x4 lumber dimensions, but are formed using 16 ga. steel plate and bracing. These tops and seats are strong and light weight.

Looks like 2x4 but has the strength of steel. Formed steel channel (SC) components approximate 2x4 lumber dimensions, but are formed using 16 ga. steel plate and bracing. These tops and seats are strong and light weight.

Formed steel channels (SC), steel end caps and understructure bracing are pre- assembled at the factory. So onsite assembly is easier.

After assembly each component is thermoplastic coated (/T) in your choice of colors. Use “/T” plus color letter in model number to specify color choice.

Thermoplastic coated steel components are available on most 6’ and 8’ rectangular picnic tables and some benches. See product pages for specific materials available.

To request a color sample send Customer Service an e-mail.

Thermoplastic Coated Steel Strap, Cut Steel Plate, and Formed Steel Channel Components

Several steel components (besides expanded and perforated steel) can be also be finished with a thermoplastic coating. See above for a process description. These different steel component designs have different Model Number designators. Then a “/T” plus the color letter is added for the thermoplastic finish. See Chart:

| STEEL MATERIAL | THERMO-PLASTIC COATED STEEL AVAILABLE ON THE FOLLOWING: |

|---|---|

| Formed Steel Channel (SC) | Most Rectangular Picnic Tables (6' & 8'); CXB, AB, APB and WMB Benches (6' & 8') |

| Steel Strap (SS) | CN-R/SS3-36 trash receptacle; CN-R/SS3-ASH ash receptacle; P-23 Planter |

| Cut Steel Plate (SP) | B70 and B120 benches; T-series round tables; CN-R/SP2-32 trash receptacle |

| Other Steel Products | B20 bike rack, HRP and HRE bike racks; T-246 flat steel lid; CN-EXP52 park policeman receptacle |

100% Recycled Plastic

Timbers, planks, and frames

Our recycled plastic material is 100% recycled high-density polyethylene and is formed using a combination of post-consumer and post-industrial waste plastics. There is no virgin plastic in this product. Post-consumer plastic has been used by a consumer and then recycled to avoid dumping in a landfill (such as milk jugs). Post-industrial plastics have gone through a manufacturing process but never reached the consumer (such as product rejects or process wastes). On average our product is 80% post consumer and 20% post industrial (percentages can vary). Our plastic components are 100% recycled and can also be recycled again and again. There are no toxic chemicals in this product. Plastic by its very nature does not leach.

A solid color is formed throughout the component and a UV stabilizer is added for ultraviolet protection. This recycled plastic is a dense, durable product, offering a long lasting, attractive appearance. It will not splinter or rot, and is resistant to mold and insects. These components are molded into solid dimensional shapes corresponding to nominal lumber dimensions. Recycled plastic components are available in your choice of colors.

To request a color sample, email our Customer Service Dept.

NOTE: These color samples are approximations only. Colors may vary by lot. There may also be variations in color translations over the Internet and by different monitors and printers used to view the colors.

Graffiti Removal suggestions for Recycled Plastic

Our recycled plastic lumber is extremely chemical resistant to very harsh chemical removers. There are several graffiti removal tools on the market that could be used on our plastic lumber. Harsh graffiti removers like MEK, NextGen and Gasoline solutions will not harm the plastic lumber. Be sure to wash off any residue. If the substance is ground in, oily or sticky, some type of solution will be needed to loosen up the stain to get it out of the porous surface of the plastic lumber.

Pressure washing with detergent added will remove most dirt, grime, markings and debris. When pressure washing, start with the tip far away, and then gradually move closer to the plastic lumber to avoid gouging the plastic lumber with too aggresive of a pressure wash.