Our History - Celebrating 63 Years in 2022

R.J. Thomas Mfg. Company, Inc. Celebrates Over 60 Years in Business

1959 to 2022 ....

Enjoying the Outdoors for over 60 Years!

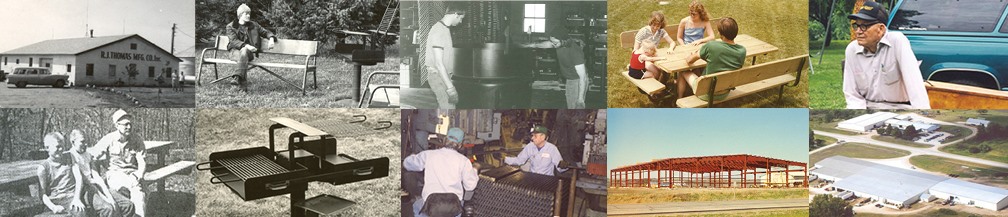

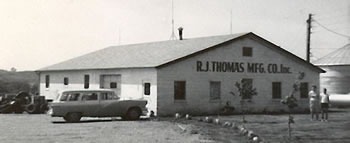

R.J. Thomas Mfg. Company was officially incorporated on May 1 in 1959 by R.J. and Doris Thomas, the result of a lifelong vision held by R.J. As a child, he was fascinated by anything mechanical and dismantled old Maytag washing machines. He worked with his peers in high school to build a glider.  As a student at Iowa State College, R.J. discovered the discipline of engineering and knew that’s where he belonged. Married to Doris Morrill on Christmas Eve in 1939, R.J. worked in the Methods (Design) Department of John Deere in Waterloo, Iowa, designing tractors. Eventually he returned to his hometown, Cherokee, Iowa, as shop superintendent at Caswell Manufacturing to make the first hydraulic loader, a labor-saving device for farmers losing their helpers to WWII. After serving in the U.S. Naval Construction Battalion as Machinist’s Mate, First Class, in the South Pacific, R.J. continued as shop superintendent at Caswell’s until 1959 when he followed his lifelong dream to own his own business and manufacture his own designs.

As a student at Iowa State College, R.J. discovered the discipline of engineering and knew that’s where he belonged. Married to Doris Morrill on Christmas Eve in 1939, R.J. worked in the Methods (Design) Department of John Deere in Waterloo, Iowa, designing tractors. Eventually he returned to his hometown, Cherokee, Iowa, as shop superintendent at Caswell Manufacturing to make the first hydraulic loader, a labor-saving device for farmers losing their helpers to WWII. After serving in the U.S. Naval Construction Battalion as Machinist’s Mate, First Class, in the South Pacific, R.J. continued as shop superintendent at Caswell’s until 1959 when he followed his lifelong dream to own his own business and manufacture his own designs.

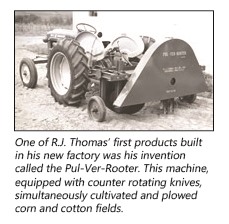

The first building was built in June of 1959, about 3 miles south of Cherokee, to manufacture R.J.’s  innovative invention, the Pulver Rooter with counter-rotating knives, which simultaneously cultivated and plowed corn and cotton fields. Later an insecticide bander was developed which proved very popular. Custom design work eventually led Thomas Mfg. into the park equipment business.

innovative invention, the Pulver Rooter with counter-rotating knives, which simultaneously cultivated and plowed corn and cotton fields. Later an insecticide bander was developed which proved very popular. Custom design work eventually led Thomas Mfg. into the park equipment business.

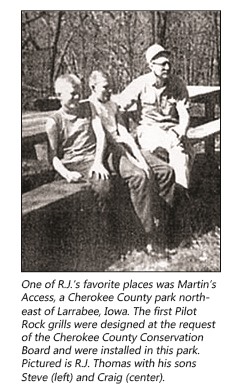

In the early Sixties John Gilchrist of the Cherokee County Conservation Board approached Thomas about designing and building grills for the newly developed Martin’s Access County Park. Thomas and Gilchrist worked together to evolve a satisfactory grill design. The new grill proved to be durable, useful and popular with picnickers and campers. If a park wanted a grill, then of course, it also needed a picnic table. Or maybe a  bench. And so, the product line began to expand from customer demand.

bench. And so, the product line began to expand from customer demand.

By the late Seventies, the company made the decision to make park equipment its predominant product line and agriculture products were discontinued. Today, R.J. Thomas Mfg. Co. Inc. is nationally and internationally recognized for its Pilot Rock brand of park, streetscape and campsite products.

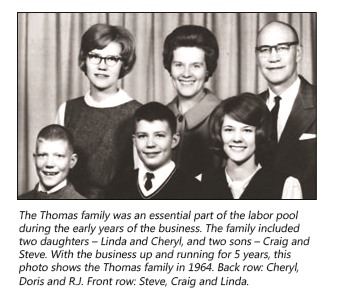

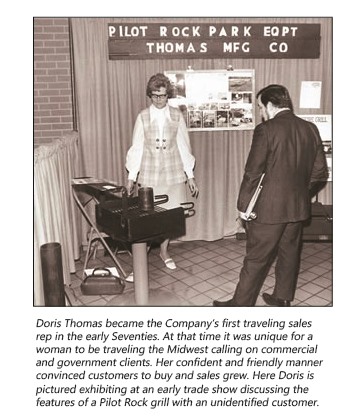

As with all small growing family businesses, the family has been an integral part of the labor pool. Supporting R.J. in all endeavors, Doris handled the sales, finances, and the office. She even became the first traveling salesperson for the company, calling on park commissioners and exhibiting at trade shows throughout the Midwest in an era when that was unusual for a woman. Her confident, friendly demeanor won over the customers and sales grew. The family includes two daughters and two sons, each working alongside their parents as they and the business grew. Daughters Cheryl and Linda, as teenagers, assisted making mailing lists, preparing mailers, sorting bolts, and helping in any way they could. Sons Craig and Steve became involved from childhood working side by side with their father throughout their teen years, returning to the business after college and eventually taking charge. Craig, the eldest son, educated as an engineer, took on the jobs of manufacturing, research, product design, productivity, and building expansion. Steve with a business degree took on finances, human resources, sales, and public relations. It was this balance of interests, talents, and education between Craig and Steve that made R.J. confident to eventually step aside.

taking charge. Craig, the eldest son, educated as an engineer, took on the jobs of manufacturing, research, product design, productivity, and building expansion. Steve with a business degree took on finances, human resources, sales, and public relations. It was this balance of interests, talents, and education between Craig and Steve that made R.J. confident to eventually step aside.

Today, R.J. and Doris are deceased. Sons Steve and Craig are still involved locally. Linda and Cheryl live in other states with their families, but remain involved as owners and board members. R.J. and Doris would be exceedingly proud to know that their business is moving on to the third generation with grandsons Adam and Andy.

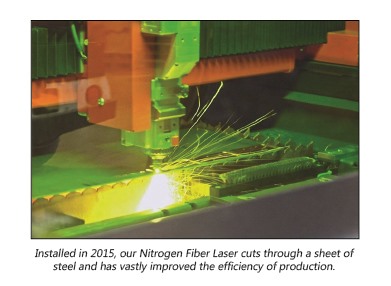

Beginning in the late Seventies, Craig began to modernize and automate the company’s physical plant and production facilities. This ongoing program continues today. As the demand for its park equipment grew, the company required different and newer steel processing and handling machinery. And as R.J. Thomas Mfg. Co. becomes an ever-larger player in the site equipment industry, the updated production facilities help keep it competitive and increase production capacity.

Beginning in the late Seventies, Craig began to modernize and automate the company’s physical plant and production facilities. This ongoing program continues today. As the demand for its park equipment grew, the company required different and newer steel processing and handling machinery. And as R.J. Thomas Mfg. Co. becomes an ever-larger player in the site equipment industry, the updated production facilities help keep it competitive and increase production capacity.

The physical facilities of the company have been expanded and enlarged 10 times since 1980, plus 2 major expansions and upgrades of the office facilities. The latest 30,000 sq. ft. factory expansion was completed in 2019. This one expansion is over 6 times larger than R.J.’s original building. The company made a commitment to automate the welding, production and finishing operations wherever possible. That decision initiated what has become a regular process of evaluating the manufacturing facilities and incorporating upgrades when needed – from physical plant to machinery to layout to software.

The company employs a growing staff of robot welders and computer-controlled machinery of various descriptions, including lasers, steel forming and cutting and digital printing. The growth and automation are leading to a regular effort to streamline workflow throughout the plant. This often leads to more expansion and modernization … and the process repeats itself.

descriptions, including lasers, steel forming and cutting and digital printing. The growth and automation are leading to a regular effort to streamline workflow throughout the plant. This often leads to more expansion and modernization … and the process repeats itself.

A common question is, “How did R.J. Thomas come up with the brand name “Pilot Rock” for his grills and tables?” Geography had much to do with it. Across the highway from where Thomas built his first factory is a huge glacial rock (measuring 20 ft. high by 40 ft. wide and 61 ft. long). Whether traveling by river or over land, the early native Indians and then the pioneers used the rock as a landmark to navigate by, so it became known as “Pilot Rock”. Today it is still a local landmark and the object to view from a rest area along U.S. Highway 59. To read more about the Pilot Rock landmark click here.

The Pilot Rock line includes 7 basic product categories: charcoal grills, campfire rings, picnic tables, park and athletic benches, trash and recycling receptacles, bike racks, and site amenities. These 7 basic categories explode into literally thousands of possible product permutations of size, design, material and colors. We estimate that we could build 27,062 different picnic tables before we would repeat one. In 1995 the company’s catalog was 36 pages long. Today’s catalog is 124 pages.

The Pilot Rock line includes 7 basic product categories: charcoal grills, campfire rings, picnic tables, park and athletic benches, trash and recycling receptacles, bike racks, and site amenities. These 7 basic categories explode into literally thousands of possible product permutations of size, design, material and colors. We estimate that we could build 27,062 different picnic tables before we would repeat one. In 1995 the company’s catalog was 36 pages long. Today’s catalog is 124 pages.

As the product line expands, the customer base grows, too. Or is it the other way around? For years the traditional customer was the government park system at the township, city, county, state and federal levels. This base has grown to include privately owned campgrounds and RV parks as well as schools and colleges, commercial customers, landscape architects, golf courses, churches and recreation facilities. Even the private residential homeowner is becoming a customer since the company built its first website in 1996.

The company continues to grow. Today it employs 72 people, and is proud of its 60-year track record of continuous employment, never having a layoff. Many employees have worked with the Thomas family for years, even decades. We have nine people with 15-20 years of service; seven with 20-25 years; four with 25-30 years; and seven with over 30 years. Every year at the company's Christmas Party, employees who have reached a milestone (20, 25, 30 years etc.) are presented with a plaque in appreciation of their dedicated service.

R.J. Thomas Mfg. Co. Inc. has always been a strong supporter of the local community as a way to give back to the towns where the employees live, and to the organizations to which they belong. The company donates regularly to academic programs in the area school systems, to local volunteer fire departments, county conservation programs (including a donation to enlarge the Martin’s Access county park where our product line was born), and other worthy causes. It gave generously to a campaign to build a local community college campus and conference center, and to the expansion of the Cherokee public library, the museum and aquatic center. It also supports the local area economic development efforts as being essential to the progress of the people and businesses of Cherokee County. The company is a member of the Cherokee Chamber of Commerce and supports many of its programs with additional sponsorships. For several years we built floats for the Chamber's annual Lighted Christmas Parade

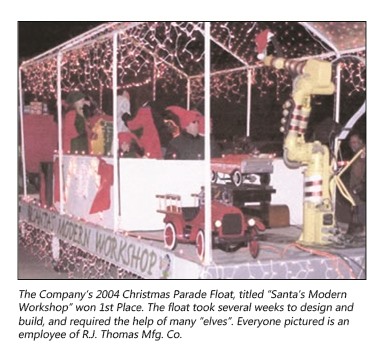

R.J. Thomas Mfg. Co. Inc. has always been a strong supporter of the local community as a way to give back to the towns where the employees live, and to the organizations to which they belong. The company donates regularly to academic programs in the area school systems, to local volunteer fire departments, county conservation programs (including a donation to enlarge the Martin’s Access county park where our product line was born), and other worthy causes. It gave generously to a campaign to build a local community college campus and conference center, and to the expansion of the Cherokee public library, the museum and aquatic center. It also supports the local area economic development efforts as being essential to the progress of the people and businesses of Cherokee County. The company is a member of the Cherokee Chamber of Commerce and supports many of its programs with additional sponsorships. For several years we built floats for the Chamber's annual Lighted Christmas Parade  (one float included an 8 ft. diameter snow globe, another demonstrated Santa's workshop with a welding robot from our factory). About every 8 weeks the Life Serve Blood Bank bus arrives and employees are encouraged to donate – on company time. In 2018 our volunteers donated 135 units of blood, saving or positively impacting 405 lives according to Life Serve Blood Center.

(one float included an 8 ft. diameter snow globe, another demonstrated Santa's workshop with a welding robot from our factory). About every 8 weeks the Life Serve Blood Bank bus arrives and employees are encouraged to donate – on company time. In 2018 our volunteers donated 135 units of blood, saving or positively impacting 405 lives according to Life Serve Blood Center.

In 2018 R.J. Thomas Mfg. became a charter participant and donor to launch the Cherokee County Promise Program. An endowment was created by all the participating organizations to provide scholarships to Western Iowa Tech Community College for students in fields designated as high demand occupations for Cherokee County. By signing on to the Promise program, students can receive full scholarships to cover the cost of their education.

For the 2018-19 school year R.J. Thomas Mfg. joined the Partnership in Excellence program. Local businesses “adopt” an elementary or middle school class, and then educate them about what we do and what kind of professions are available locally. We signed on to work with a 2nd grade class. Our winter project let the boys and girls customize their own Christmas tree ornament design. Then they toured our factory to see how the ornaments were designed in CAD. The highlight of the tour was watching the laser cut their own ornaments out of a sheet of stainless steel. Each student got a personal ornament for their tree.

For the 2018-19 school year R.J. Thomas Mfg. joined the Partnership in Excellence program. Local businesses “adopt” an elementary or middle school class, and then educate them about what we do and what kind of professions are available locally. We signed on to work with a 2nd grade class. Our winter project let the boys and girls customize their own Christmas tree ornament design. Then they toured our factory to see how the ornaments were designed in CAD. The highlight of the tour was watching the laser cut their own ornaments out of a sheet of stainless steel. Each student got a personal ornament for their tree.

Over these 60 years, R.J. Thomas Mfg. Co. has developed a diverse product line under its Pilot Rock brand, and has an international reputation. But every company, regardless of size, is only as good as its people. The company  depends on many hard working, dedicated and skilled men and women who perform the myriad tasks required to take a raw piece of steel ... or wood or recycled plastic..., turn it into a product and deliver it to the customer. And make it look easy! As more and ever-changing technology is employed in every process from sales to fabrication to finishing to packaging to shipping, we will need well-trained and skilled crew members to make it all work.

depends on many hard working, dedicated and skilled men and women who perform the myriad tasks required to take a raw piece of steel ... or wood or recycled plastic..., turn it into a product and deliver it to the customer. And make it look easy! As more and ever-changing technology is employed in every process from sales to fabrication to finishing to packaging to shipping, we will need well-trained and skilled crew members to make it all work.

Bob, known as “R.J.” to all employees, and Doris Thomas took every opportunity to stress the importance of family and personally treated all employees as “extended family”. They always showed a genuine interest in, and concern for, everyone’s well-being. The second- and third-generation Thomas family continues to express this attitude and spirit today. To R.J. and Doris, family came first, and it was important for them and the company to promote and participate in employee activities and events to foster that “family bond”.

For decades the company has regularly sponsored annual picnics and barbecues where employees and families enjoy the outdoors, great food (cooked on a Pilot Rock grill), and maybe softball games and swimming. At holiday time, the annual Christmas party brings employees and spouses/partners together for fellowship. We are still a small company, so these social events encourage a spirit of fun and camaraderie among the staff at R.J. Thomas Mfg. Co.

“Our company is only as good as its people,” says Steve Thomas. That philosophy drives the company daily to strive for improvement by investing in training and education for our staff; by investing in local community programs to make our area a better place to live; and by investing in production facilities to make our Pilot Rock products a better choice for our customers. R. J. Thomas Mfg. has been implementing that philosophy for 60 years as the company and the product line continue to grow. Doris Thomas was the company’s first sales person knocking on doors and exhibiting at trade shows. Today, trade shows are still part of the mix, but most customer contact happens through the catalog, telephone and our web site. Plus, sales through other online retailers and catalog resellers and independent sales reps. Times have changed, but we plan to always have something new “on the (CAD) drawing board.”